Custom Plastic Toy OEM & ODM Manufacturing

PVC Figurines, Plush Toys & Electronic Toy Production for Global Brands

KingDa is a professional custom plastic toy manufacturer providing full OEM & ODM manufacturing solutions for global brands, distributors, and private label toy buyers.

From concept design, 3D modeling, and mold development to injection molding, mass production, and retail-ready packaging, we offer complete end-to-end toy manufacturing services.

We specialize in PVC figurines, collectible toys, plush toys, and electronic & IoT toys, combining creative design with strict quality control and scalable production capacity.

Backed by our experienced R&D team and advanced factory facilities in China, we ensure stable bulk supply, competitive wholesale pricing, international compliance, and long-term partnership support.

Custom Plastic Toy Manufacturing Solutions

KingDa is a professional custom plastic toy manufacturer with an experienced R&D team and advanced factory facilities in China. We help global brands, distributors, and private label buyers develop and manufacture competitive toy product lines — from concept design and 3D modeling to mold development, sampling, and mass production.

Custom Plastic Toy Solutions

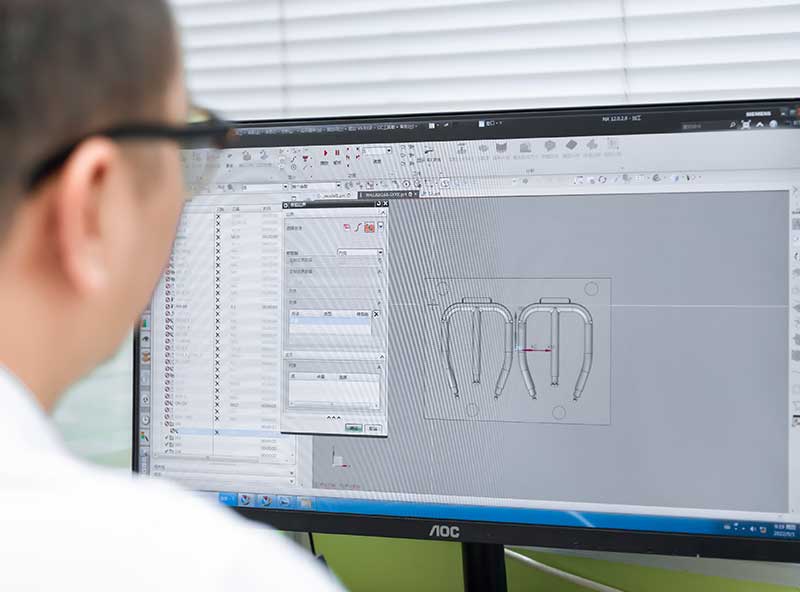

1. Concept & Design Development – We support concept design, 3D modeling, structure engineering, and prototype sampling, ensuring your toy meets brand positioning, safety standards, and production feasibility from the earliest stage.

2. Mold Development & Injection Molding – With advanced mold tooling and precision injection molding technology, we guarantee accurate detailing, stable structure performance, and scalable mass production capacity for wholesale projects.

3. Material & Function Customization – We offer flexible material options including PVC, ABS, TPR, and plush materials, along with integrated electronic modules such as sound, LED lighting, motion sensors, and interactive functions.

4. Quality Control & International Compliance – All projects follow strict quality control procedures and comply with international standards including BSCI and ISO 9001 certification, ensuring export-ready manufacturing.

5. Branding & Retail-Ready Packaging – We provide complete private label manufacturing solutions, including logo printing, custom packaging design, retail-ready display packaging, barcode labeling, and export carton management, supporting efficient wholesale distribution worldwide.

Advanced Plastic Toy Manufacturing Capabilities

KingDa combines engineering expertise, precision tooling, and scalable production systems to deliver high-quality custom plastic toys for global brands and wholesale buyers. Our manufacturing process is built around efficiency, consistency, and long-term reliability.

1. Structural Engineering & Design Optimization – We refine every 3D model, product structure, and internal assembly to ensure durability, safety compliance, and cost-effective mass production. Our engineering team focuses on wall thickness control, joint strength, mold feasibility, and long-term structural stability for scalable production.

2. Precision Mold Tooling System – Our in-house mold tooling workshop supports high-precision development, multi-cavity optimization, and efficient cycle-time control, ensuring consistent detailing for PVC figurines, ABS plastic toys, and promotional products, enabling stable bulk production.

3. Injection Molding & Assembly Control – Through advanced injection molding technology, automated production lines, and controlled assembly workflows, we maintain consistent quality across large-scale wholesale orders while minimizing defect rates and improving yield stability.

4. Surface Finishing & Detailing – We provide professional spray painting, pad printing, silk screen printing, and UV coating, delivering accurate color matching and premium surface quality for collectible toys and retail-ready products.

5. Quality Assurance & Production Testing – All projects undergo strict quality control inspection, including material testing, structural validation, drop testing, and final packaging review. Our factory operates under BSCI and ISO 9001 certification standards, supporting export-ready manufacturing for global markets.

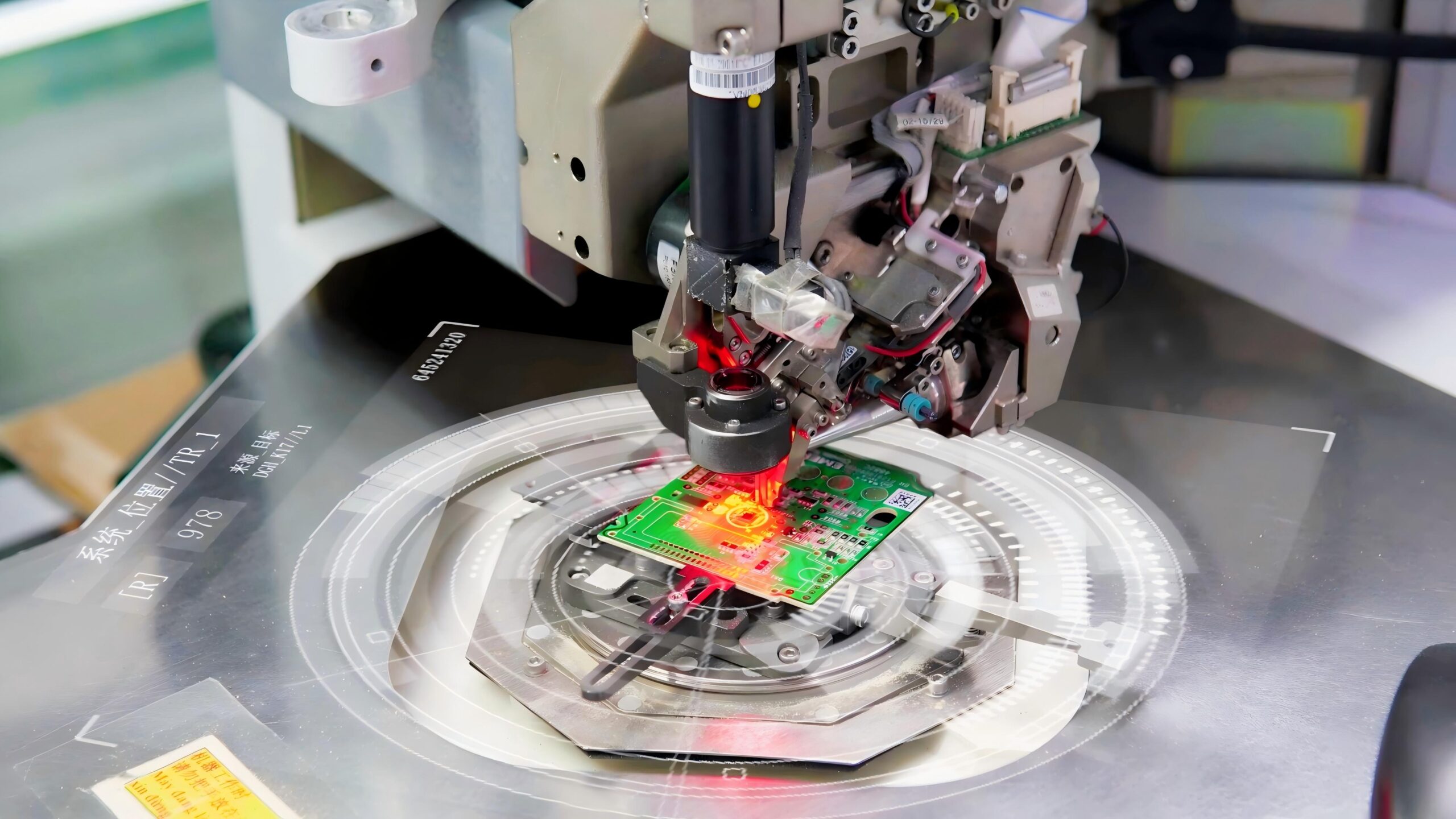

Custom Electronic & Smart Toy Development

For brands and private label projects that require enhanced functionality and interactive features, KingDa provides fully customized electronic & IoT toy manufacturing solutions with scalable production support and stable long-term supply.

1. Electronic Module Integration – We integrate sound modules, LED lighting systems, motion sensors, voice chips, and smart control boards, ensuring stable circuit design, safe voltage management, and consistent performance across mass production.

2. Firmware & Function Customization – Functions such as sound playback, light synchronization, touch activation, timed response, and interactive sequences can be customized based on your product positioning and target market requirements.

3. Structural & Safety Engineering – Our engineering team optimizes internal layout, wire routing, battery housing design, and drop-resistance structure to ensure child safety compliance and durability standards for global markets.

4. Production Stability & Assembly Control – Through standardized assembly workflows, circuit testing procedures, and aging tests, we maintain low defect rates and stable yield performance for bulk wholesale orders.

5. Branding & Retail Packaging Integration – We support private label solutions, including logo integration, customized startup effects, retail-ready packaging, barcode labeling, and export carton configuration for global distribution.

Custom PVC Figurines & Collectible Manufacturing

KingDa develops custom PVC figurines and collectible toys for global brands, distributors, and private label buyers. We combine creative design precision with scalable mass production to ensure stable bulk supply and consistent detailing quality.

1. Sculpting & Prototype Development

We support 3D sculpting, digital modeling, and hand-painted prototype sampling to refine proportions, detailing accuracy, and brand aesthetics before mass production.

2. Precision Mold Engineering

Our in-house tooling system ensures high-accuracy mold development, multi-cavity optimization, and stable injection cycles for PVC figurines and collectible toys, enabling reliable bulk production.

3. Injection Molding & Detailing Control

Using advanced injection molding technology, we maintain sharp edges, clean parting lines, and consistent structure performance across large-scale wholesale orders.

4. Painting & Surface Finishing

We provide professional finishing techniques including spray painting, pad printing, hand painting, gradient effects, and protective coating to ensure color accuracy and retail-quality presentation.

5. Packaging & Brand Integration

We support private label packaging, barcode labeling, retail-ready display boxes, and export carton management to streamline global wholesale distribution.

You Can Trust KingDa for Your Custom Toy Manufacturing Projects

KingDa provides one-stop custom plastic toy manufacturing solutions, including PVC figurines, collectible toys, plush toys, and electronic & IoT toys.

From concept design and mold development to injection molding, assembly, and retail-ready packaging, we support full OEM & ODM manufacturing projects for global brands, distributors, and private label buyers.

What Custom Toy Manufacturing Services Can KingDa Provide?

KingDa provides comprehensive custom plastic toy manufacturing services, covering structural design, material selection, electronic integration, and retail-ready packaging. We support full OEM & ODM toy production tailored to your brand positioning and market requirements.

We offer end-to-end customization including:

1. Product Appearance & Structure Design

(housing design, character sculpting, internal structure optimization, logo areas)

2. Mold Engineering & Tooling Development

(high-precision mold tooling, multi-cavity optimization, cycle time control)

3. Material & Functional Integration

(PVC, ABS, TPR, plush materials, sound modules, LED lighting, motion sensors)

4. Electronic & Smart Module Customization

(voice chips, control boards, battery housing design, firmware tuning)

5. Branding & Private Label Solutions

(logo printing, retail-ready packaging, barcode labeling, export carton design)

6. International Compliance & Factory Certification Support

(EN71, ASTM F963, CPSIA, BSCI, ISO 9001 production standards)

Whether you are launching a new toy line or scaling an existing collection, our engineering and manufacturing teams work closely with you to ensure stable mass production and long-term wholesale supply.

Who Is This Custom Toy Manufacturing Service For?

If you belong to any of these groups, KingDa can help you build competitive private label toy product lines with stable production and long-term supply support.

Importers & Trading Companies

Reliable manufacturing capacity and export experience are critical for trading companies.

KingDa provides stable mass production, export-ready documentation, quality consistency, and flexible OEM & ODM cooperation models to support your global distribution business.

Wholesalers & Distributors

For wholesalers and distributors, product differentiation matters.

We support private label manufacturing, exclusive mold development, and customized packaging solutions so you can build your own branded toy collections and reduce direct price competition.

Brand Owners & Toy Startups

Launching a new toy line requires strong development support.

From concept design, 3D modeling, and prototype sampling to mold tooling and mass production, our team ensures your products meet safety standards and market positioning from day one.

E-commerce Sellers & Private Label Brands

Online sellers need unique products with stable quality and compliance.

We help you develop differentiated collectible toys, PVC figurines, plush toys, and smart toys with retail-ready packaging, barcode labeling, and scalable supply capacity.

Toy OEM / ODM Manufacturing Process

Project Inquiry & Product Brief

Share your product concept, target market, materials, function requirements, estimated quantities, compliance needs (EN71, ASTM F963, CPSIA), and packaging expectations. Our team reviews all key details before project evaluation.

Concept Design & Feasibility Evaluation

We assess structural feasibility, material selection (PVC, ABS, TPR, plush), electronic integration options, cost structure, and production timeline. An initial quotation and development plan will be provided.

3D Modeling & Prototype Sampling

Our R&D team creates 3D models, internal structure layouts, and engineering prototypes. For figurines, we provide sculpting and hand-painted samples for approval before mold development.

Mold Development & Engineering Testing

High-precision mold tooling is developed in-house. Samples undergo structural testing, drop testing, functional testing (for electronic toys), and safety validation to ensure compliance and durability.

Mass Production & Quality Control

After final approval, we begin injection molding, assembly, painting, and finishing under strict quality control procedures. Production follows BSCI & ISO 9001 standards with batch inspection and yield monitoring.

Packaging, Shipping & Long-Term Supply

We provide private label packaging, barcode labeling, export carton management, and global shipping coordination. Stable long-term production capacity ensures scalable wholesale supply.

Proven Production Capacity. Trusted Worldwide.

At KingDa, we focus on execution, quality control, and long-term partnership.

With years of experience in custom plastic toy manufacturing, we have built strong cooperation with global brands, distributors, and private label buyers. Below is a snapshot of our production strength and global performance.

Customer Satisfaction

Global brands and distributors trust our custom plastic toy manufacturing with consistent quality, stable supply, and long-term partnership support.

Annual Production Capacity

Scalable injection molding and assembly production lines ensure stable bulk orders for PVC figurines, plush toys, and electronic toys.

OEM / ODM Projects Completed

From concept development to mass production, we have supported hundreds of private label toy projects across global markets.

Countries Served

Export-ready production with BSCI & ISO 9001 standards, supporting global wholesale distribution and international compliance.

Contact us

Contact KingDa Now!

FAQ

What products do you supply?

We specialize in custom plastic toys, PVC figurines/collectibles, and plastic & electronic consumer products, all designed for global wholesale and distribution.

Do you have in-stock items for fast shipping?

Yes, we keep a range of popular products in stock to ensure fast shipping and minimal lead times.

What certifications do your lights have?

Our products are backed by strict quality control and various certifications, including CE, RoHS, and ISO, ensuring safety and top-notch quality.

Can I get a sample before placing a bulk order?

Yes, we offer sample orders to help you evaluate the quality of our products before making a bulk commitment.

What is your MOQ for wholesale orders?

Our minimum order quantity (MOQ) for wholesale orders varies depending on the product, but we aim to accommodate various customer needs.

Do you support private label or logo packaging?

Yes, we provide private labeling and custom packaging options to help you build your brand with confidence.

Low MOQ

Meet the different ordering quantities requirement

Economical

The affordable price and highest quality among all the suppliers

Always in Stock

If you place an order, we will ship it in 7 days or less

2-Year Warranty

Our each product comes with 2-year warranty

Get A Free Quote

- MOQ 1000 sets to customize the product.

MOQ 100 sets to buy our branded product. - Get FREE projects and E-catalog link once you sign up!